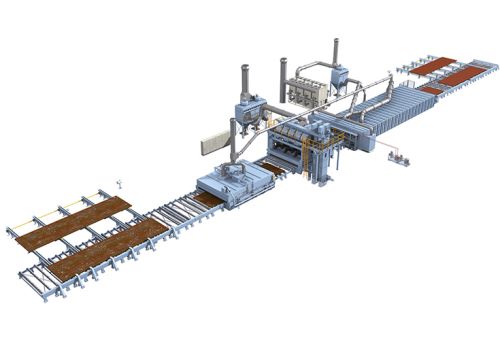

A Preservation line usually consists of:

- In-and out-feed roller conveyor (sometimes equipped with a cross conveyor to increase the efficiency)

- Pre-heater to heat up and dry incoming material (this enables the later-applied paint to dry more quickly)

- Roller conveyor shotblast machine (to treat plate widths between 1.5 and 5m, with working speeds of 1.0 – 10m/min)

- Spray booth to coat the freshly cleaned steel material with a layer of water or solvent-based primer to achieve a temporary corrosion protection

- Drying tunnel with slat conveyor to transport and dry the newly painted material and the continuous drying on the way to the exit of the tunnel

Specific features such as: combined direct flame and hot air circulation pre heating ovens, automatic width detection and wheel adjustment, TITAN wheels, and clean detector system make Wheelabrator Preservation lines the number one choice.

Technology:

Wheelblast

Application:

Cleaning

Preservation Lines

Preservation lines combine the heating (drying), blasting, coating and drying of workpieces such as sheet steel, profiles, pipes or steel structures in one automatic line.