The 8 "Module8" Principles

- Flexibility

- Wear reduction

- Ease of maintenance

- Safety

- Productivity reliability

- Process reliability

- Quality

- Short delivery times

Defining the right airblast machine is notoriously complex. Wheelabrator has developed the Module8 principles to ease the decision making process and ensure that the right solution is developed for your application.

Module8 is a set of eight principles defining the very core of Wheelabrator’s airblasting business. Through understanding these eight principles the right solution for your application can be assured.

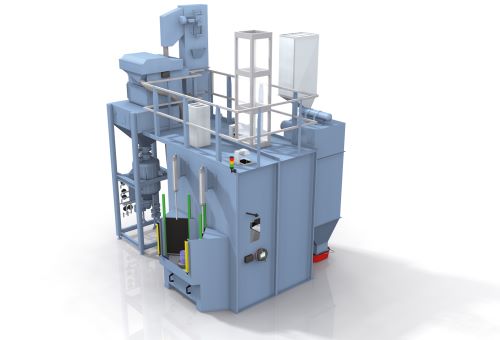

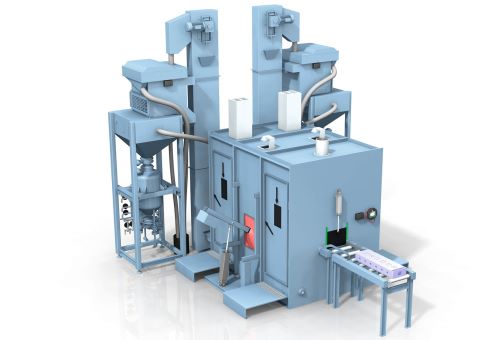

The Module8 range comes with a comprehensive set of safety features as standard. The cabin is designed with safety in mind, as all components are fitted to the exterior of the cabin for ease of access and increased safety. The cabin is designed with safety in mind, as all components are fitted to the exterior of the cabin for ease of access and increased safety.

There are multiple locations on the machine for the HMI panel so that the operator can function or close down the machine from multiple locations both on ground level and whilst on the roof of the machine.

The machines are fitted with a “dead man” switch function – By pushing the dead man switch during service and maintenance work, the moving machine components can be safely serviced.

Airblast

Cleaning

Highly flexible machine range, with one or two satellite tables, for light up to heavy parts.

Airblast

Cleaning

Highly flexible machine range, with one or two turntables, for light up to heavy parts.

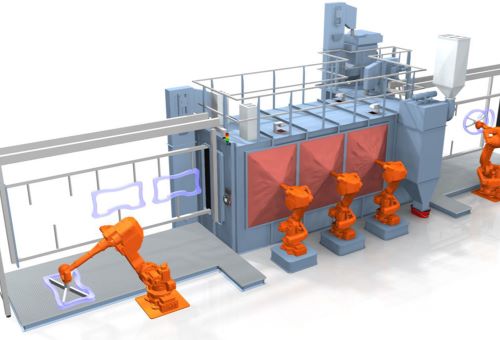

Airblast

Highly flexible machine range, with two to four frames, for light up to heavy parts.

Internal airblast machines reliably blast interior cavities of simple or complex castings, for example cylinder head bores and water jackets, crank cases, engine blocks and suspension components.