Wheelabrator Special Shotblast Machines

With our global engineering and production facilities, we are able to provide custom built machines that serve your needs, your application, your specification and your budget.

Take a look at our Innovation and Technology pages, and the Design and Development pages, for an insight into how we can provide solutions to your challenges. Alternatively, find your "Industry" page relevant to your application, and see some of the solutions Wheelabrator has provided for similar components.

Any blast machine type can be adapted and re-engineered to fit your application to become a "Special" solution, below are just a few of our more complex machine types.

Special Machine Examples

Technology:

Wheelblast

Application:

Cleaning

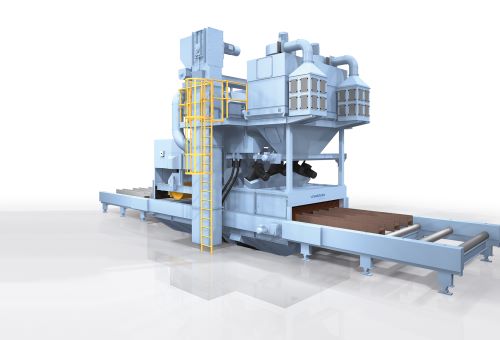

Roller Conveyor Type HD

The HD roller conveyor range demonstrates the highest performance variants of this machine type for blasting sheet metal and profiles.

Technology:

Wheelblast

Application:

Rust and Heat Scale Removal

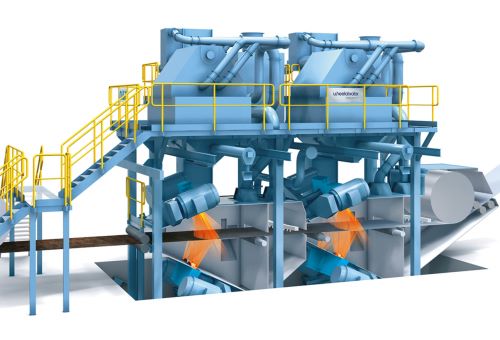

Construction Blaster Type X

With angled wheels for welded constructions, flame cut parts and fabrications

Technology:

Wheelblast

Application:

Cleaning

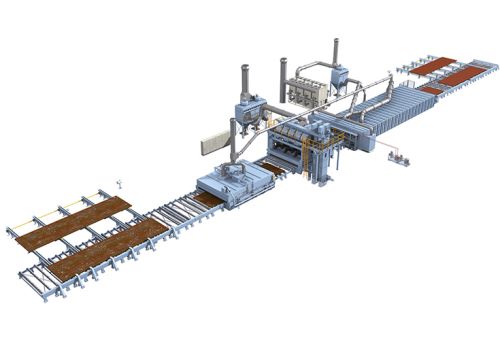

Preservation Lines

Preservation lines combine the heating (drying), blasting, coating and drying of workpieces such as sheet steel, profiles, pipes or steel structures in one automatic line.

Technology:

Wheelblast

Application:

Cleaning

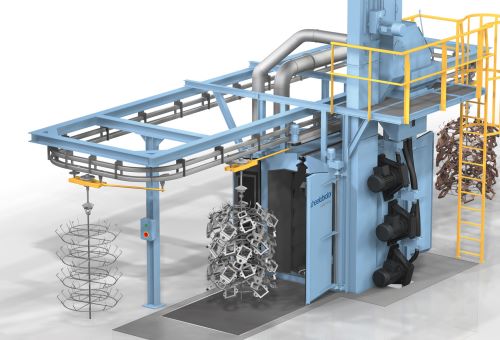

HT Hanger Type Machine

Include a number of heavy duty variations for different production areas, e.g. foundries and forges.

Technology:

Wheelblast

Application:

Cleaning

DHB Pass-Through Monorail Type D

DHB Pass-Through Monorail Machine type D will serve many applications.

Technology:

Wheelblast

Application:

Cleaning

Pass-Through Monorail Type C

Achieves short blasting times due to a combination of the latest transport technology and highly efficient blast wheels.

Technology:

Wheelblast

Application:

Cleaning

CT Through Feed Blast Cleaning Machine

CT machines are situated within either an automated process or a continuous production line. The systems are equipped with an endless apron conveyor and between 2 and 6 blast wheels.

Technology:

Wheelblast

Application:

Cleaning

DT Through Feed Rocker Barrel Machine

The principle using drum-type machines is a leading technology today. The polygon shaped trough rocks back and forth to gently tumble the workpieces. Continuous shot blast machines automate production sequences and improve the work environment.

Technology:

Wheelblast

Application:

Cleaning

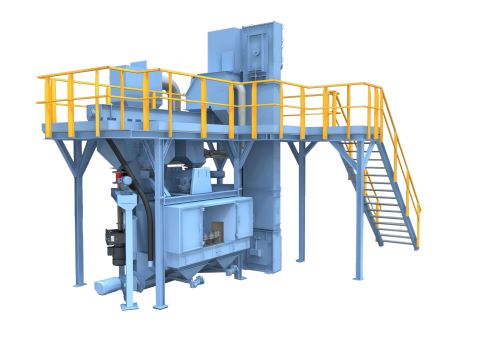

IBC Inclined Belt Conveyor Machine

Process safe blast cleaning of rotation symmetric workpieces with smooth and shock-free transport in continuous rotation. This machine ensures consistent and uniform exposure of the workpiece under the blast stream, and is ideal for high quality blasting of lighter parts that would be damaged in a tumblast system.

Technology:

Wheelblast

Application:

Cleaning

HB Strip Descaling Machine

Descaling of narrow-, medium-, and wide steel strip with clear benefits. Blast cleaning systems can be adjusted to various strip widths and quality grades and will enable practically any output demand.

Technology:

Wheelblast

Application:

Cleaning

Robot Gripper

Wheelabrator Robot Gripper machines are ideal for the removal of fire cracks, for shot peening and the blasting of filigree parts.

Technology:

Wheelblast

Application:

Cleaning

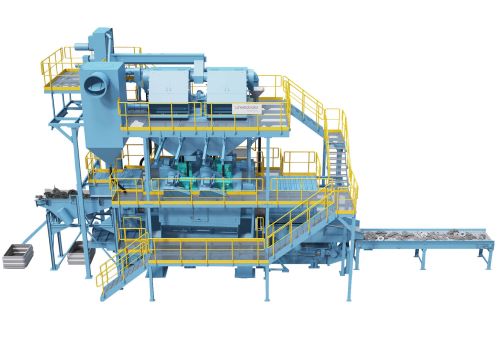

DS and DV Manipulator Systems

These systems meet the highest production demands and are renowned for their excellent blast cleaning performance for components of different shapes and sizes. These systems deliver outstanding performance due to their high process capacity and excellent cleaning efficiency.

Technology:

Wheelblast

Application:

Rust and Heat Scale Removal

Satellite Turntable Shot Blast Machine

Highly precise satellite turntable shot blast machines from Wheelabrator have been specially developed for use in the automotive industry.

Technology:

Wheelblast

Application:

Shot Peening

RDS Spring Peening Machine

Shot peening systems for suspension, valve and leaf springs.