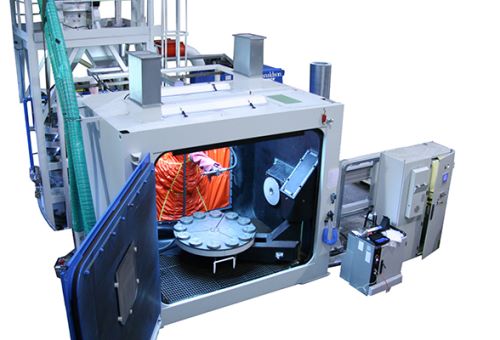

Table machines

The table machine's essential component is the turntable for handling the workpiece. This kind of machine is best suited to processing symmetrical parts, for example:

- large gears

- engine disks

- shafts

- moulds

- wheels

- casting moulds

However, the turntable can be positioned at certain angles to allow the processing of asymmetric parts alongside multiple positioned manipulators or robot guided nozzles.

Wheelabrator has developed a variety of table machines to meet the requirements of our customers with regards to their material flow. In addition to the traditionally fixed tables and turntables there are machine types with one or two mobile turntables. These machines reduce process times as new parts can be loaded while others are processed.

A specialty of Wheelabrator Group is table machines with one or two swing-in turntables at the front of the blasting cabinet. This significantly reduces processing times and the space requirement for the machine.

TT Table machines are our standard offering and highly flexible, built in the Module 8 principle.

Technology:

Airblast

Application:

Cleaning

Turntable Machine TT

Highly flexible machine range, with one or two turntables, for light up to heavy parts.

Technology:

Airblast

Application:

Shot Peening

MP 2TR4 Cell

Automatic and Compact Two-table Peening System. The CNC MP 2TR4 machine has been designed for peening and blasting complex rotary components associated with the aerospace and automotive industries.

Technology:

Airblast

Application:

Cleaning

MP 600 Cell

The state-of-the-art in aerospace shot peening, the MP 600 range processes small aero-engine components to improve or restore their resistance to fatigue; including turbine discs, fan discs, compressor rotor discs, spools, shafts and blades made from steel, Inconel, aluminium or titanium alloys.

Technology:

Airblast

Application:

Cleaning

MP 1000 Cell

MP 1000 is Wheelabrator's solution for aero-engine peening and blasting processed. Representing the state-of-the-art in aerospace shot peening, the MP 1000 range can process the widest variety of aero-engine components to improve or restore their resistance to fatigue.

Technology:

Airblast

Application:

Shot Peening

MP 1200 System

The MP 1200 multi-purpose CNC peening machine is ideal for the shot peening and surface treatment of automotive gears, crown wheels and shafts, and aerospace discs and blades.

Technology:

Airblast

Application:

Shot Peening

MP 1500 System

The MP 1500 range can process the widest variety of aero-engine components to improve or restore their resistance to fatigue. For aero jet engine components to 1500mm ⌀ and 1000mm H (or 2000mm ø in TI XL version).

Technology:

Airblast

Application:

Shot Peening

MPR 1500 Robotic System

MPR 1500 machine is specifically designed for the aeronautic and gas turbine industries with 1 robot and 4-8 Satellite Tables.

Technology:

Airblast

Application:

Shot Peening

MPR 1500 LDG System

For ID + OD shot peening of various complex landing gear components (internal and external surface peening).

Technology:

Airblast

Application:

Shot Peening

MPR 2200 Robotic System

Robot Satellite Table Machine with complete process reliability, for aeronautic and gas turbine applications.

Technology:

Airblast

Application:

Shot Peening

MP2R 1500 Robotic Peening

Two-Robot Satellite Table Machine with complete process reliability with 6-20 satellites, for aeronautic and gas turbine applications.

Technology:

Airblast

Application:

Shot Peening

MP 2TR7 Peening Cell

Compact two-table automatic peening machine for peening and blasting complex rotary components associated with the aerospace industry.