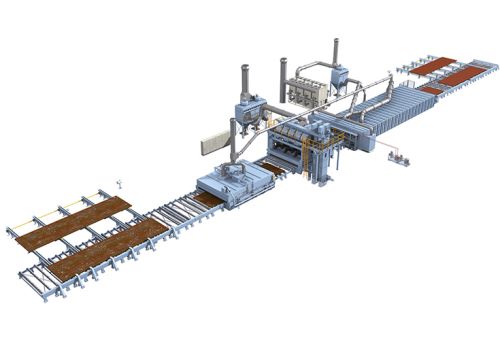

The Preservation Line

The first part of the treatment process occurs on a preservation line, which incorporates the different stages of blasting and priming. On the preservation line, sheets and profiles are thoroughly blast cleaned and provided with a temporary corrosion protection coating. Along with the external transport unit, a preservation line consists of a pre-heating oven, a pass-through blasting machine (roller conveyor type), a painting unit and a drying tunnel with its associated slat conveyor. Wheelabrator is the only company that offers roller conveyors and preservation lines that can blast 5m wide steel plate at high quality - and we're working on larger sizes.