Light-weight castings (sand, gravity, die-cast) need appropriately designed desanding, deburring and surface preparation technologies. This is reflected in the range of Wheelabrator shot blast systems available for light metal castings.

The right machine for your process will depend upon the complexity of the casting, your production method, part size and number and product flow. Contact us to discuss your application.

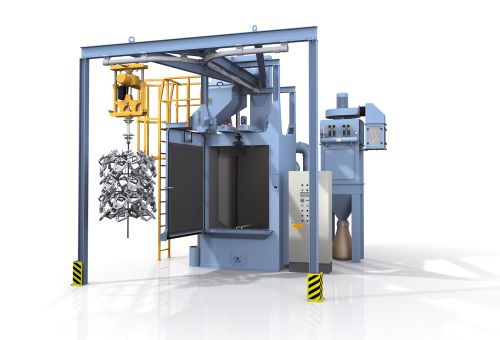

Hanger Type Machines for Light Metal

Fully Automatic Continuous, and Flexible Blast Cleaning on Wire-mesh Belt Machines

High Performance Processing And Finishing

Batch Tumblast Machines

Technology:

Wheelblast

Application:

Cleaning

MB Batch Type Tumblast Machine

Compact batch-barrel design with a simple operating principle to deliver forced but gentle turning and tumbling of the parts.

Technology:

Wheelblast

Application:

Rust and Heat Scale Removal

Super III Tumblast Machine

Super III Tumblast are designed for blast cleaning foundry, forge and mill duty parts and components.

Hanger Type Machines

Technology:

Wheelblast

Application:

Cleaning

HTS Hanger Type Machine

Standard solution ideal for foundry and forge applications, including cast, forge or hardened parts.

Technology:

Wheelblast

Application:

Cleaning

SPH Spinner-Hanger Machine

The machines with two or three chambers are applied for surface treatment and deburring of aluminum parts, descaling of forgings, and sand removal from castings, especially for those workpieces which are not suitable for tumbling because of their shape or size.

Technology:

Wheelblast

Application:

Cleaning

HB Hanger type blast machines

Wheelabrator’s Overhead Monorail Machine offers total flexibility for your surface preparation requirements.

Manipulator Machines

Technology:

Wheelblast

Application:

Cleaning

Robot Gripper

Wheelabrator Robot Gripper machines are ideal for the removal of fire cracks, for shot peening and the blasting of filigree parts.

Technology:

Wheelblast

Application:

Cleaning

MAC Robot Manipulator System

The system is designed to accommodate specific requirements for shot blasting workpieces of light metal or magnesium alloys and has an internal manipulator to move the workpieces in the blast stream.

Technology:

Wheelblast

Application:

Cleaning

DS and DV Manipulator Systems

These systems meet the highest production demands and are renowned for their excellent blast cleaning performance for components of different shapes and sizes. These systems deliver outstanding performance due to their high process capacity and excellent cleaning efficiency.

Mesh Belt Machines

Technology:

Wheelblast

Application:

Cleaning

MeshBlast Machine

Designed for cleaning a variety of parts that range from die-cast transmission housing with hard to reach areas to simple workpieces and components.

Technology:

Wheelblast

Application:

Cleaning

MAXMESH® Machine

Ideal for cleaning small, low profile parts and components such as cut out metal shapes.