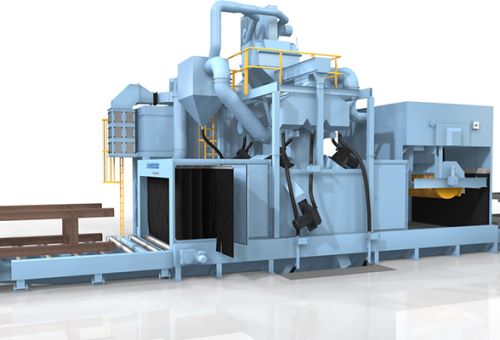

Bernhard Hahner: "Until now, we’ve always had our shotblasting done externally. Integrating the blast machine tightens complex processes, shortens storage times, generally improves the quality of our outputs and reduces risks associated with handling and transport. It also allows us to offer flexible and cost-effective subcontract shotblast services here in Germany, within incredibly easy distance of our customers."

All further transport of the workpiece – to work stations or further processing equipment – is also fully automated. In principle, Hahner is not against the manual distribution workpieces, diverting them off long roller conveyors towards their destined next work step. However, in a busy production environment, it can quickly become quite taxing for the operator to keep an eye on the movements of each and every part and remembering, which part is needed at which welding station.

That’s why a roller conveyor track can be automated as a CNC axis, enabling the predetermination at planning stage of end points for every piece of material. After the last process step, each piece travels to its final destination without further manual interference and can be unloaded at exactly the right point.

When it comes to workpiece logistics and various loading tasks before and between process steps, automation and clever integration can unlock considerable cost-savings at forward-thinking companies like Hahner.

While drill and saw lines have been able to process profiles automatically for some time, the loading of shorter pieces in particular has remained a manual job. This is where the magnetic loading system on a FICEP saw comes in, with straightforward automation allowing an interrupted workflow through the machine and reducing the physical strain on the operator, who previously had to lift and shift heavy cut ends.

Operators also no longer have to constantly keep an eye on every work step, to intervene correctively, smooth away obstacles or unload parts intended to skip a certain process. At Hahner, all this is now done automatically, reliably and without supervision.