Wheelabrator’s wire and bar descaling machines are renowned for their reliability and multi-shift capabilities

The process of mechanical descaling can be considered as an “environmentally responsible” non-polluting alternative to chemical descaling. Wire, bar, tubes and profiles can be blast cleaned in a single or multistrand method.

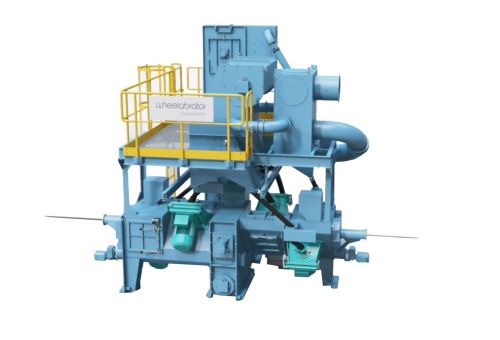

Designed as 3, 4 or 6 wheel machines, Single- or multistrand longitudinal blast machines not only meet different capacity requirements, but can be optimally adapted to changing product runs. These shot blast machines are easy to integrate into modern drawing lines operating at speeds of up to 240m/min or can be used as stand-alone machines for autonomous finishing.

Wheelabrator Billet Descaling Machines operate on the single-strand longitudinal blast cleaning principle and are usually arranged ahead of crack detection equipment. Integration in fully mechanized finishing lines results in a continuous material flow however, Wheelabrator billet descaling machines can also be used independently with loading and unloading devices and storage tracks. The number of wheels in operation depends on the production needs. The descaling degree is adapted to the surface quality required by the flaw detection method.

Technology:

Wheelblast

Application:

Cleaning

FL Wire and Bar Descaling Machine

The FL machines are renowned for their reliability and multi-shift capabilities.