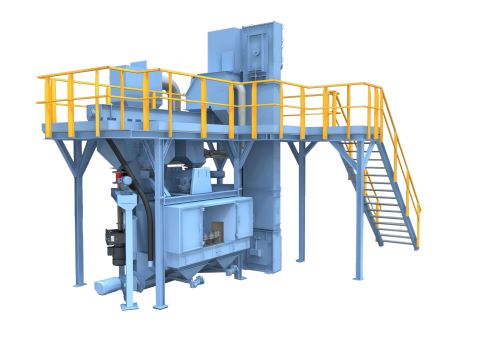

Satellite table blast system

The essential component of a satellite table machine is the indexing mechanism which rotates the workpiece through fixed positions within the blasting machine. Smaller symmetrical parts are best processed in this kind of machine, although Wheelabrator has also designed satellite table machines to process engine blocks and other non-symmetrical workpieces. The satellite table concept provides the advantage that new parts can be loaded and unloaded while others are processed.

Wheelabrator provides highly precise satellite table machines which are specifically designed for use in the automotive and aerospace industry. The machines are often used for peening as well as cleaning applications as precise, homogenous results are achieved. These machines can be combined with robots for automatic loading and unloading to create fully integrated manufacturing cells as part of a continuous/in-line process.

Depending on the component size, the application and your process type, tables can be designed to incorporate from 2 to 36 individual satellites.

Technology:

Wheelblast

Application:

Rust and Heat Scale Removal

Satellite Turntable Shot Blast Machine

Highly precise satellite turntable shot blast machines from Wheelabrator have been specially developed for use in the automotive industry.