Peik's Patents

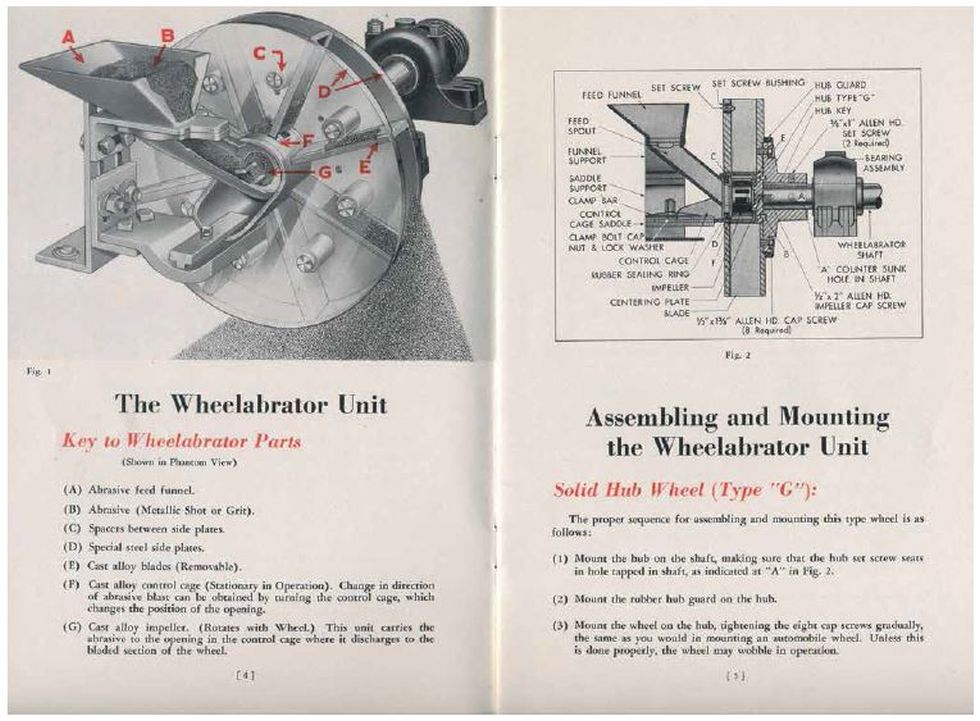

Some would say that Louis D. Peik, of the American Foundry Equipment Co., invented wheelblasting with a patent in 1933.

As the machine threw an abrasive by a wheel-like device, the term "Wheelabrator" was born.

In 1933, the new Wheelabrator machines were launched with great success, and in 1935, Tilghman's in the UK started to build licensed Wheelabrator machines.

In 1945, American Foundry changed its name to American Wheelabrator & Equipment Company. In 1966 it acquired 40% of Tilghman's, and the company became Tilghman Wheelabrator - which then became fully owned by American Wheelabrator in 1973.