Simplicity means being able to exchange a part easily, it means a machine that is fit-for-purpose – without frills that can become sources of error.

All frills, no gain?

Where a whole foundry consists of chains of machines, failure in one stops production in all. Every potential source of downtime is a risk to the whole operation.

So why add unnecessary complexity in the first place? Because it’s not a conscious process – it just happens unless you actively try to avoid it. As blast and peening processes are getting more complex and process control demands are becoming more stringent, it is very easy to end up designing a machine that matches that complexity.

Add to this that, in many areas of industry, automation is on the march, adding more and more sensors and components to machines as standard, and customers can easily end up with a machine that is simply over-equipped for their needs.

It’s down to us, as an equipment manufacturer, to pay extra attention to this and make sure customers don’t receive a machine that can potentially collect a lot of process data, with no capacity to practically do anything with that data.

The challenge: designing out complexity

So what is the answer to this complexity problem? It’s making the effort and having the confidence to make machines simpler. Quite often, the complexity is still there – in the process, in the integration, in the specification, but it’s down to our engineers to design machines that are beautifully simple regardless.

Our philosophy at Wheelabrator, particularly in recent years, has been to focus on this “customer/user experience” aspect. Wherever we can, we ensure we deal with the complexity so our customers don’t have to. To do this, it helps to have your ear to the ground.

As machine fitters, we can keep an eye out for practical improvements that become apparent when you see the machine in its natural production environment and spend time at the customer’s. We can then feed back to our engineers at our technology centres and in R&D.

Evolving simplicity

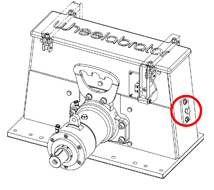

An example of this is the evolution of the side opening mechanism of a blast wheel. It’s a seemingly small detail of the design, but if you work in maintenance in a foundry, it’s what stands between you and servicing the internal parts of the wheel. This drawing shows an actual design that we fed back on, in conjunction with the maintenance team at the customer, an iron foundry in Austria:

What we – as fitters – took issue with here is the number of bolts you have to loosen to open the lid. Surely there’s a better way of designing this! It turns out there is, saving the maintenance guys valuable time when dismantling and reassembling the wheel:

To open this mechanism, the maintenance guys only need a hammer and a steel bar!

It’s the sum of all these little things that makes maintenance easier and results in a robust machine that lasts – even if it does a complicated job. The message to equipment manufacturers and the lesson we’ve taken to heart here at Wheelabrator: don’t get carried away, stay down to earth, and listen to your machine fitters!